As a labor-intensive sector, manufacturing especially witnesses few takers as the idea of digital transformation fuels the fear that tools like automation may take away jobs. However, digital transformation has now emerged as more than a necessity to keep businesses afloat. As a result, leaders can no longer ignore the fact that they will have to embrace it and develop a digital transformation roadmap.

Since developing a strategy requires foreseeing the challenges involved, here are some impediments that you can expect on your digital transformation journey:

As stated above, the greatest resistance that you can anticipate would be from your workforce. The fear of job security or the change in job positions will make your employees fear digital transformation. It also has close relations with how we humans generally operate. We find comfort in monotony, and experiencing change is quite unsettling.

Hence, when you announce the decision to undergo digital transformation, you must follow it up by busting the myths surrounding it and amplifying its related benefits. Educating and empowering your staff and upskilling their talents could make them more willing to join the cause.

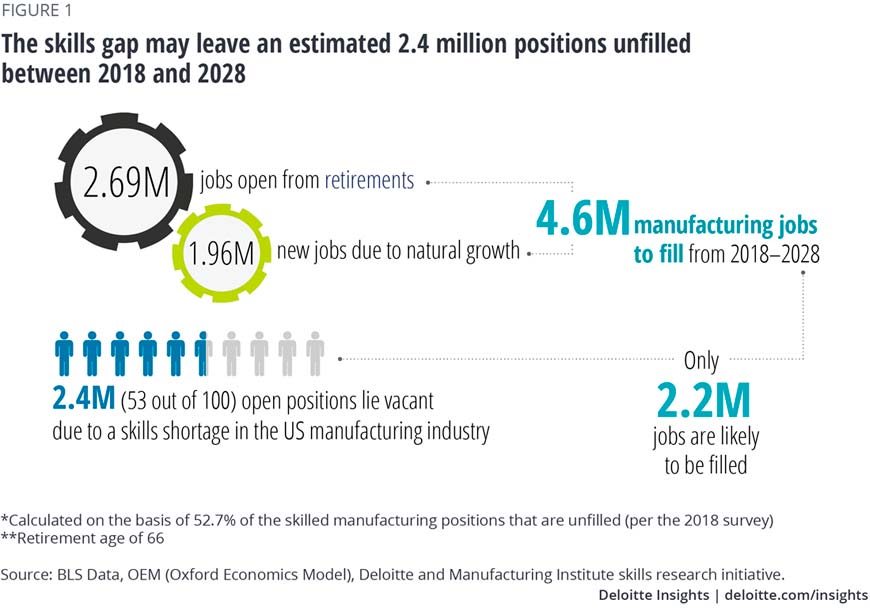

Even though you may like to retain your existing workforce and train them to ease into their new roles, you will have several job positions that need to be filled. Now, since digital transformation produces the need for modern skills, you might face issues while finding appropriate talent. Presently, the world is facing a grave mismatch between the skills and experiences of human resources versus the in-demand roles.

When it comes to operating manually, cybersecurity may not feature as a prominent consideration. However, the moment digital technologies are introduced to the mix, it becomes of prime importance.

With the popularity of the Industrial Internet of Things (IIoT), you will be dealing with real-time data that plays a critical role in managing your assets. And as your setup converges with an IT framework and gives rise to networked devices, you would need to take measures that such channels of communication are safe and secure at all times.

It is worth mentioning that following a data-centric approach can get difficult. Simply extracting or generating data is not enough, and you will have to discover ways to utilize it.

Whether you need data to identify bottlenecks or to introduce automated operation - data must be available in its usable format. Given that the manufacturing sector may produce high volumes of data, you also need proportionate data processing capabilities to extract meaning.

As is evident, digital transformation will require introducing several tools and techniques, which makes it critical to inculcate a tech-savvy mindset from the ground up.

Needless to say, digital transformation may attack the very roots of your manufacturing business.

Due to the highly dramatic nature of this change, you will have to restructure the entire business model to accommodate digital transformation. Such changes are not easy to navigate and can range from investing in digital tools and technologies to remodeling your shop floor.

Every transformation, no matter how small, will require tenacious commitment and in-depth planning. As such, businesses should also prepare to bear its impact and innovate to keep up with the fundamental changes.

When carried out correctly, digital transformation in manufacturing can lead to a high degree of flexibility and near-infinite scalability. However, the intermediary stages of digital transformation, which involve large-scale experimentation, decrease the scalability of your operations significantly. In fact, you may observe marginal inflexibility even in comparison to manual operations!

For instance, the downtime that takes place during recruitment, onboarding, and training will bring production or innovation to a standstill. Resultantly, your capacity and time to market may take a hit, even if it is transitional and temporary. Hence, if you wish to maintain business continuity, you may have to develop alternative plans to facilitate it.

Hence, when you announce the decision to undergo digital transformation, you must follow it up by busting the myths surrounding it and amplifying its related benefits. Educating and empowering your staff and upskilling their talents could make them more willing to join the cause.

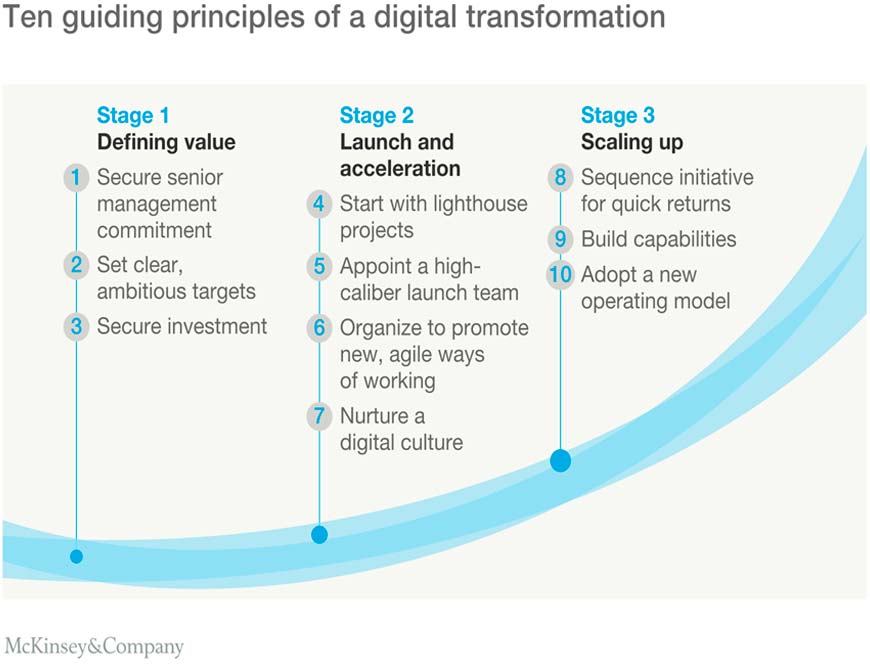

While digital transformation may present several opportunities, it also comes with its fair share of challenges. However, once you decide to take the plunge, it is best to stay committed to it and fight against the roadblocks.

Your first line of action should include formulating a reliable digital transformation guide that will include a clearly defined starting point and end results. And while you are at it, prioritize integrating your legacy system with the new business model, lest you are planning a complete overhaul. Either way, the results would be well worth the efforts as you will derive long-term benefits!

About the Author:

Peter Jacobs

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.