Embarking on a journey spanning two decades, Lungmetall OHG, a dynamic medium-sized enterprise, has undergone a remarkable metamorphosis. From its origins as a specialist in anchoring solutions for the natural stone industry, the company has evolved into a leading system supplier for sheet metal and machining technology. Established in 1924 as a locksmith specializing in forging tools for the natural stone sector, Lungmetall expanded its horizons in 1972 with the industrial production of anchoring elements for building cladding. This transformation was not without its challenges, as Marcus Lung, grandson of the founder and authorized representative at Lungmetall, recounts: "Our processes did not keep pace with our transformation, leading to a decline in profitability."

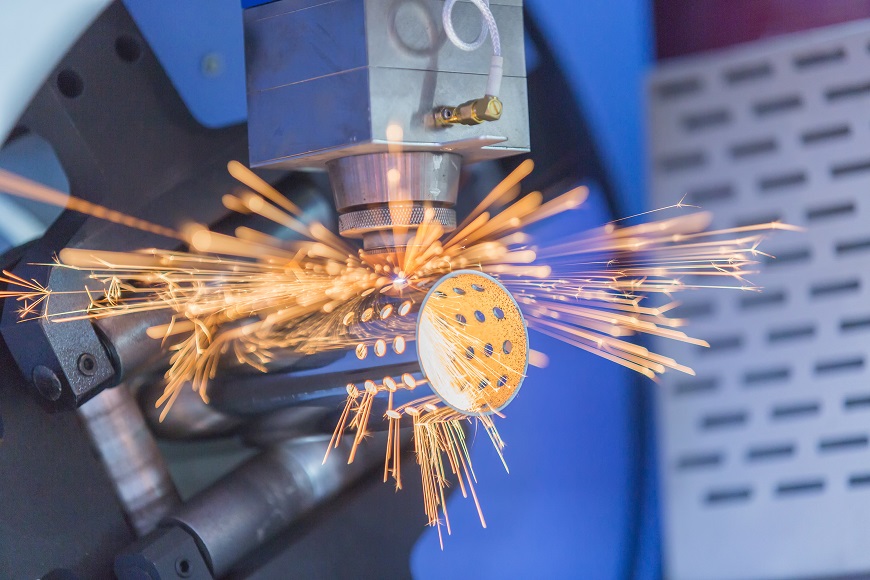

Since his arrival at Lungmetall in 1997, Marcus Lung has been instrumental in driving the company’s evolution. With fervor and foresight, he introduced water jet and laser cutting machines, diversifying their offerings and gradually penetrating new customer segments in machinery construction. Lungmetall has since emerged as a distinguished system supplier with extensive manufacturing capabilities, successfully captivating clientele across diverse sectors including natural stone, beverage and food, pharmaceuticals, medical technology, aerospace, tool and mold making, motorsports, and vehicle manufacturing.

Unveiling the Imperative for Change:

Amidst this period of growth, Lungmetall recognized the pressing need for a robust ERP system. Just in the nick of time, they discovered Lantek, a solution perfectly tailored to their burgeoning needs. Marcus Lung elaborates, "We had no time to define processes during our growth, and we lacked proper production planning because our ERP system couldn’t handle laser processing or assembly components. The ERP component of the machine software we used at that time also did not align with our requirements." Joel Schubert, project manager and machine technician, adds, "Back then, every technician made offers without any coordination. Sometimes, plates from the warehouse were earmarked for offers multiple times, leading to perfect chaos when all were accepted simultaneously."

"Others have only isolated solutions – Lantek has everything we need."

Lungmetall embarked on their software quest with the intention of finding a suitable ERP system. However, fate had other plans. Upon encountering Lantek, skepticism loomed large. Yet, as Marcus Lung, a key figure at Lungmetall, recounts, the second encounter was revelatory. Lantek wasn’t just another software provider; they were a comprehensive solution. In Marcus’s words, "With Lantek, we can map almost all our processes." Unlike competitors offering isolated solutions, Lantek emerged as the beacon, encompassing both CAD/CAM and ERP functionalities—the ultimate one-stop-shop.

"A functional software needs detailed knowledge of what happens in the factory hall."

Understanding Lungmetall’s journey requires grasping the unique challenges faced by sheet metal manufacturers. Christoph Lenhard, Commercial Director of Lantek Germany’s office underscores the importance of tailored solutions, emphasizing that no off-the-shelf software can capture the intricacies of sheet metal fabrication. Lantek’s strength lies in its adaptability and manufacturer independence. This freedom from proprietary constraints resonates deeply with Marcus Lung, who values the flexibility to choose machinery independently. Lung’s decision to partner with Lantek wasn’t just about software—it was about liberation from industry norms.

Exploring Capabilities, Embracing Support:

Lung’s journey with Lantek wasn’t just a transaction—it was a partnership grounded in exploration and understanding. Visits to other Lantek customers provided invaluable insights, illuminating the software’s potential in real-world scenarios. Yet, beyond the product, Lungmetall found solace in Lantek’s personalized support. A team that wasn’t just responsive but deeply attuned to Lungmetall’s needs, offering guidance and clarity every step of the way.

In the dynamic landscape of sheet metal manufacturing, Lungmetall’s story stands as a testament to the power of strategic partnerships and the transformative impact of innovative software solutions. With Lantek by their side, Lungmetall isn’t just navigating change—they’re shaping it.

"The software accompanies every part through production."

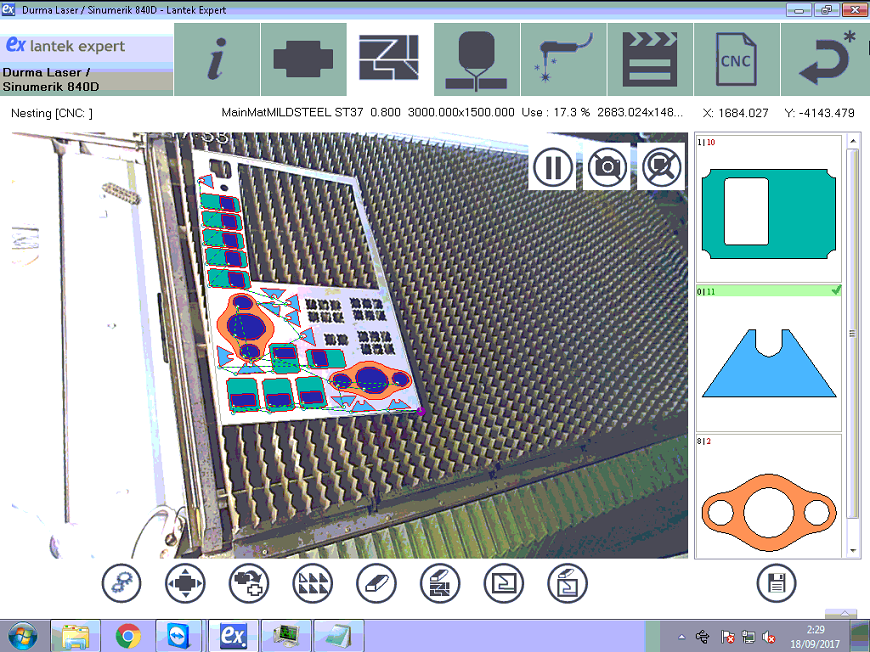

In 2018, Lungmetall started with the implementation of Lantek’s 2D-CAD/CAM software, Lantek Expert, and the 3D solution, Lantek Flex 3D. Subsequently, they incorporated Lantek Integra for enterprise management and Lantek MES for production control and warehouse management. In Lungmetall’s halls, cutting-edge, partially unmanned laser cutting, water jet cutting, and bending presses from Bystronic, milling and turning machines from DMG Mori, and a saw from Amada stand. The software covers all processes and accompanies every part through production – whether water jet cutting, punching, laser cutting and sawing, welding, turning and milling, bending, deburring, shot blasting, and tumbling, or laser engraving, marking, and anodizing. Additionally, the software supports all other processes, from quotation creation through production and assembly/picking to shipping and invoicing, including material and warehouse management.

Although there was initially some internal resistance among technicians and production employees, Lung says, "We knew that if we didn’t map all these processes in Lantek, we couldn’t continue to grow." Eventually, the realization set in that the initial effort in data capture ultimately saves time and costs for the entire company. Differences between the past and present start with the calculation of offers. Lung emphasizes, "An offer must reflect real prices and be profitable for us – consistently, no matter who creates it." Previously, technicians entered data into up to seven different Excel files, resulting in two different offers from two different employees. Schubert adds, "Some customers eventually figured out that it’s worth making a second inquiry because the results often differed significantly." But that’s not all: "For example, when there was an order with a larger quantity of angled profile pieces, the price was calculated using several Excel sheets and remained fixed for us, even if the customer later ordered fewer pieces over time. This led to incorrect estimates, as the original quantity was lost in the system, and the actual material prices were not taken into account."

"Lantek replaces intuition with knowledge. ’Capturing data in Lantek takes some time, but then you have it readily available for every subsequent inquiry,’ confirms Ivonne Grudnick, Head of Sales Support. ’And through the digitization of our processes, we can determine at any time, in response to customer inquiries, exactly where each part is in production.’ On her desk lies an order from an existing customer for an assembly with more than 300 positions. Using historical data, she can pull together all parts along with their drawings. With the stored information on current material prices, setup times and costs, exact times for cutting and every other processing step, technology tables, rates, and margins per customer, component-related additional costs, and necessary purchased parts, she reliably calculates the actual costs and creates the offer. If accepted, it becomes an order with a click. Lungmetall no longer needs order entry.

Due to precise and quick calculations, the company now receives more orders. ’In laser cutting with automatic nesting, we get almost every order – and we know that we make money with it,’ says Lung, because: ’In the past, it was a gut feeling that the calculated price would somehow work out. If it was too expensive, we didn’t get the order; if it was too cheap, we lost money. Today, we know that we make money with the calculated price because it is based on precise calculations.’ Lenhard concludes, ’Lantek replaces intuition with knowledge.’

Lungmetall’s financial situation has significantly improved, thanks to cross-order, part-specific production planning and software-supported warehouse management, preventing what Production Manager Jan Caspar describes: ’Sometimes, an entire plate was cut for a single part, making the material costs higher than the price of the manufactured part.’ His boss Marcus Lung adds, ’We have a variety of standard and non-standard materials – with sheets alone, there are 66 different ones. Previously, scraps were generated that no one had on their radar. Lantek knows every scrap and its dimensions and knows exactly where it is. Scraps are nested first.’

Procurement based on real data and nesting

Procurement also benefits from Lantek. ’Previously, we estimated the need – today, we buy based on real data and nesting,’ says Lung. Project Manager Schubert summarizes, ’Without Lantek, we wouldn’t have made it through Corona and wartime. With our previous way of working, we couldn’t have handled the sometimes highly fluctuating delivery conditions and material costs.’

For some customers, there was unpleasant news, and Lungmetall had to advocate for understanding during the transition that prices now reflect actual costs. Some customers left – some returned after some time because they valued the longstanding collaboration with Lungmetall. And they received more than precise quotes. Schubert says, ’Because we used to merge data from many different programs, a lot was produced incorrectly. Today, the data goes into the system once and is available for all subsequent processes. This has reduced our rejection rate, and better production planning has significantly improved our on-time delivery.’

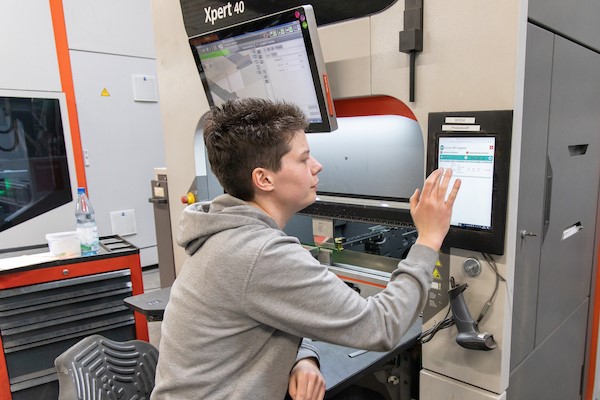

Production Manager Caspar is ’glad that the paper chaos is over, and we have an overview of everything in digital form – we can answer inquiries with a click.’ Before Lantek, all work orders were printed and distributed as a stack of paper to employees in the morning. Today, there is a short five-minute kick-off meeting in the morning, and everything else runs electronically. Instead of the many folders that were carried through the halls with orders, there are now tablets at every workstation, showing the upcoming tasks, and employees report the completed processing.

From minds to the system

With Lantek, Marcus Lung has also alleviated another concern: ’Previously, all information was in the head of an individual, usually the production manager. If he was absent, on vacation, or left the company, we lacked a lot of knowledge. Material prices, grades, previous order quantities, and solutions when unforeseeable things happened, such as a water jet machine having a certain problem – all of this has transitioned from minds to the system and is now stored in Lantek.’ And some processes were done over the years as they had become ingrained, without anyone questioning them because this know-how somehow worked. Lenhard says, ’But no one knows for sure whether this know-how is the best – that always becomes apparent with Lantek.’

To ensure that Lungmetall continues on the right path in the future, the company is planning the next step for data-based decision-making: the introduction of the cloud-based tool Lantek Analytics for data analysis to optimize processes and customer relationships."