Imagine two sheet metal plants with the same production and performance capacity, but with one fundamental difference: how they communicate, document and access information.

We’ll call the first workshop, the semi-connected manufacturer. The company has CAD/CAM and CNC machines, the usual office programs for drawing up quotes (Excel) and static production boards in the workshop for programming. The managers have daily meetings to discuss the status of production, the program for the day and any other necessary issues. The operators at the plant go to and fro with papers.

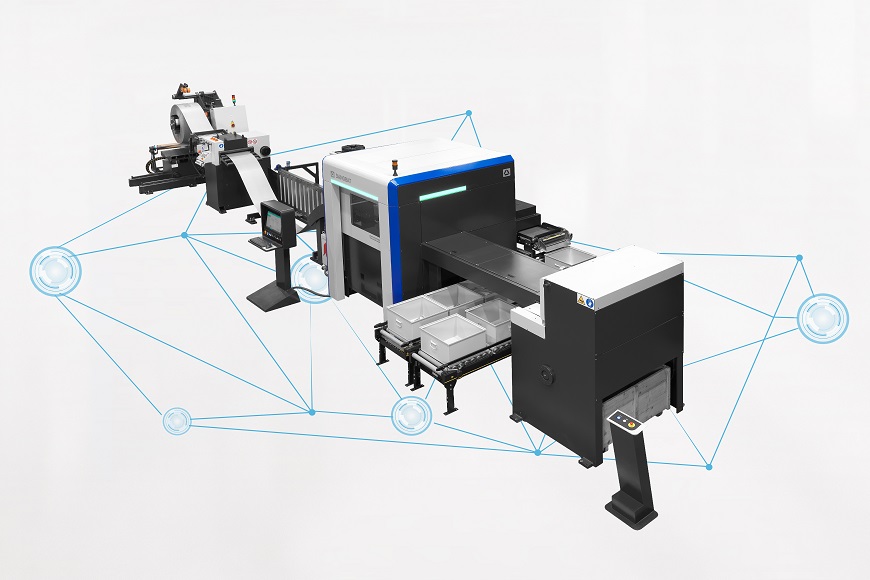

The second workshop is the connected manufacturer. They use CAD/CAM, a Manufacturing Execution System (MES) and an Enterprise Resource Planning system (ERP) with which they program and manage manufacturing and commercial operations. Their machines are Internet-enabled, which means that instructions and work orders are sent directly to the control or mobile device being used. With permit-based access to the company’s database, the decisions made by employees aren’t based on assumptions or hypotheses, but on real-time data from the workshop.

Now, imagine the following scenario. Both installations must process 100 4x2-inch laser-cut pieces in 16-gram mild steel. The client wants each piece to be bent at 90 degrees and welded to create an open box, creating a total of 50 boxes. Finally, the boxes must be powder-coated and shipped in five days. Both installations are able to process the whole job at home. Before closing the deal, how would each one manage this order, from quote request to finalization?

A client comes across a manufacturer after a third-party recommendation or, maybe, via a quick Internet search. They request a quote indicating the material, dimensions and delivery date. With this information, the salesperson sends an email requesting a file with different parts so that they can draw up a more precise quote. The staff are busy and it takes them one day to reply. At last, with their hands on the document, the vendor sends it to the production staff so that a programmer can do the nesting and calculate the time and cost of each tracking operation. With this information, the sales team then has to talk with the production manager to discuss their schedule and availability. Before committing to the delivery date requested by the client, the sales department verifies whether the order can be sent on that date or not.

With all of this information, on the second day, the vendor sends the quote to the end client, but it isn’t accepted until the third day. Now, with two days to go before the delivery date, the workshop must program and adjust the machines in order to start production on the piece. There’s a limited time frame which could result in unexpected costs if production has to roll into a third shift or costs for extra hours not included in the budget.

The client, eager to find out the status of their order, calls the vendor, who then has to call the production manager. The manager heads over to the production plant and talks to several operators to get a status update before notifying the vendor and, eventually, the client.

The client discovers the shop through a website that showcases what it does and even has an online form for requesting a quote. The client sends their quote request with all of the necessary information: contact, type of material, quantity, operations, delivery date and an uploaded DFX file. Once this information has been sent, the client receives an automatic email thanking them for their request and ensuring them that they will be contacted shortly. At the same time, the sales and production staff are notified of the request and receive all of the information and files regarding the necessary pieces so that they can start to draw up the quote.

Using connected machines and systems, the vendor starts to put together a quote while the system does the nestings, assigns operations and verifies the upcoming schedules in order to generate an end cost and date of finalization. In parallel, the production manager is notified to verify that the job can be produced. All of this happens in a matter of minutes and the quote is sent to the client within hours, or even sooner. The client reviews and accepts the terms the same day, allowing the manufacturer four full production days.

With the piece in production, the client, also eager to find out its status, calls the salesperson. With the machines and operations connected through the supervision of the production plant, the vendor looks up the order and sees exactly where it is in the production process.

The state of alarm is announced and lockdowns begin. All non-essential industries have to shut down. Manufacturers that don’t supply essential industries struggle to find ways of keeping their doors open and their employees working. Those that can remain open have to find new ways of working while maintaining social distancing and adhering to other health precautions established.

They had to ensure that they implemented the right systems in order to keep the business working as normally as possible. This meant moving the management, sales, support and engineering equipment off-site. The crisis forced everybody in all areas to adapt workflows to a workforce that was working remotely. This left everybody with a number of questions while they adapted to the new normality.

How on earth will we quote jobs with sales, management and engineering staff remotely?

For the semi-connected manufacturer, quoting jobs is difficult, especially with disparate systems. Everybody continues to quote via email, Excel spreadsheets and verbal communication by telephone or using videoconference apps. The disconnected systems in quoting and planning bring about a lack of interdepartmental communication that could be seriously harmful. Jobs can be accepted with losses or when it’s impossible to meet the promised delivery date. With some working remotely and others in the shop, everybody is making a lot of calls and sending a lot of emails just to receive status updates.

With the connected manufacturer, everybody that needs to can access the information they require in accordance with their position. The system consults the company data and generates accurate calculations in terms of production time, prices and delivery dates. It registers when each task has been completed and assigns the next one to the appropriate person.

The semi-connected manufacturer still depends on weekly or daily production meetings, which are now virtual. A project management application has been introduced for some staff to use internally, so that they can track costs, tasks and production while they look for a more permanent solution. These methods create a disconnected and cumbersome tracking system, one that depends too heavily on the human factor. Asking staff to learn new mechanisms in turbulent times, especially when they are working remotely, implies a greater risk of inappropriate application and requires a large amount of interdepartmental communication that takes up a lot of time. This makes it difficult for management to analyze operations, understand which areas are under more pressure than others and know how to allocate staff suitably.

In contrast, the connected manufacturer’s staff work remotely without a problem. They’re not working with new platforms and require no specific training. Thy have the platforms installed on their laptops. Given that they depend heavily on web-based tools, they can access the information they need from any device with an internet connection. Staff can quickly view the orders that are pending production and programming, quotes that have yet to be accepted and the requirements for each order according to their permissions. This reduces interdepartmental communication and allows Management to better understand which areas need staff and other resources.

Once the quote has been accepted in the semi-connected factory, the engineering department finalizes the programming for the job and the routing and sends it to operations. To reduce face-to-face contact, the engineers create a workflow that eliminates paper. They now use laptops and tablets at each workstation to communicate using the company’s internal chat application. When the laser operators finish cutting, they notify the next person and the engineer, who sends the instructions to the next operations right away.

Nobody can see the status of all jobs in real time. When the client calls to request an update on the status, the vendor still has to consult production to get an answer. With no methods for storing and analyzing this data, quoting still requires as many contact points as before.

The connected manufacturer has connected machines and, therefore, doesn’t notice much change in the workflow. The engineer continues to generate the programs from wherever they are and sends them to the appropriate work stations. As each process is completed, the operators validate their work using barcode scanners, entering data with tablets or making the machine control inform the company’s MES of its status.

Interested parties have access to the necessary information at any time. In addition to this, the system constantly stores data and puts together a growing set of samples, making quotes more precise and, at the same time, offering ways of implementing hypothetical situations.

Now, using laptops or tablets at the workstations, along with a project management application, the semi-connected manufacturer starts to gather information on the production status. Once again, this is a step in the right direction, but it still means that sales staff have to request information on status updates from production. In an aim to avoid an information overload, the system is configured so that only certain parties who are involved in the process can access the information. Unfortunately, this creates information silos between departments, as production may not want sales to have full access to their information.

In contrast, the connected manufacturer uses several production tracking methods, and their staff are already equipped with suitable systems for tracking production. In fact, this shop has started working online so that clients can see, in real time, when a piece has just left the laser and is headed for the next phase.

In today’s advanced factories, we find machines with Internet connections, tablets for tracking production, robotics systems for picking up pieces and other connected work cells. All of these systems can be programmed and monitored from remote locations, offering countless advantages.

While productivity and production increases, connectivity allows sales teams to provide quotes quickly and accurately. Most importantly, connectivity allows manufacturers to store and analyze up-to-date production data to make fully informed business decisions. In these times of uncertainty, when information changes so quickly, decisions backed by up-to-date data have never been so valuable.

Considering these two snapshots, which league do you want to play in, the semi-connected one or the connected one?