What is Sheet Metal Fabrication? What are its Basic Techniques?

In the world we live in, almost everything is either made of metal or has metallic components. Since the first discovery of metals back around 4000 BC, they have become the foundation of industrialization. All metals used in industrial processes start as ores.

After being extracted from mines, the ores are transported to smelting facilities where the metals are separated from the dregs. The metals are then sent to foundries, where they are melted into a liquid and cast into blocks of different shapes and sizes. Sheet metals start as long ribbons rolled out into desired thicknesses. These ribbons are then further flattened into large sheets of various lengths and thicknesses. Sheet metal fabrication is the process that comes into play at this point.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a set of multifaceted manufacturing processes that turn sheet metal into robust functional parts using different manufacturing methods. Sheet metal fabrication comprises multiple processes, from cutting and bending to surface treatment and assembling to manipulate the sheet metal in different ways. Common sheet metals include copper, zinc, steel, stainless steel, and aluminum.

Sheet metals are usually between 0.006 and 0.25 inches (0.015 and 0.635 centimeters) in thickness. The thinner the sheet metal, the more malleable it is. Thicker sheet metals are used for heavy-duty parts with strenuous applications.

When making partially flat or hollow parts, sheet metal fabrication offers a cost-effective alternative to processes like casting and machining. Sheet metal fabrication is a quick process that produces minimal material wastage and is widely used across consumer industries and specialist industries.

Let us now take a look at some basic sheet metal fabrication techniques.

What Are Some Basic Sheet Metal Fabrication Techniques?

1. Cutting

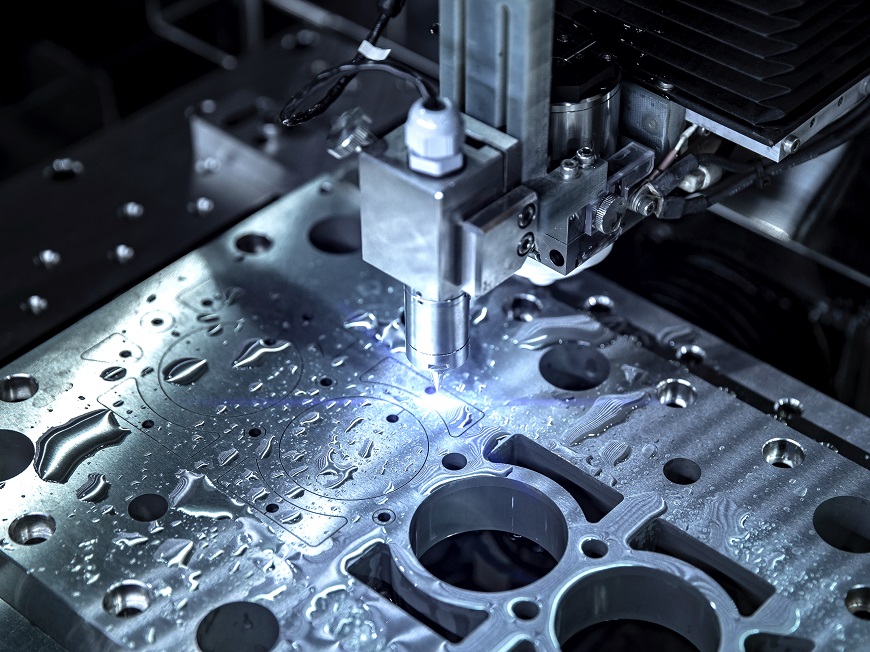

One of the most common processes in sheet metal fabrication is the cutting technique employed to divide large sheets into several parts, produce metal pieces of precise measurements, and create accurate perforations. There are several ways to perform the cutting process, including:

2. Deformation

Sheet metal deformation is another major technique of sheet metal fabrication. This process can include a variety of methods to manipulate sheet metal without cutting into it. Some common deformation techniques are:

3. Welding

The welding process is used to join sheet metals together. Various welding techniques can be employed for different kinds of metals and the thickness of the material. Given below are some common welding methods:

4. Stretching

Sometimes, sheet metals need to be stretched to remove defects. The two most common ways of achieving this are discussed below:

5. Shrinking

This sheet metal fabrication technique is used to smooth out dents in the metal. Heat shrinking and tucking are common shrinking methods used in the industry. Some companies may use shrinker machines to automate the shrinking process.

Conclusion

Numerous techniques can be used for sheet metal fabrication, depending upon your requirements. Often, a combination of methods is used to get the optimum result. The best variety of sheet metal fabrication tools differs for various kinds of projects, with the malleability of the metals you are working with being one of the major influencers.