La chapa metálica sigue dominando como material estructural en la fabricación de maquinaria y equipos gracias a su versatilidad y a las ventajas que aporta en términos de durabilidad, así como por los ahorros de material, peso y costes que permiten los avanzados métodos de procesado que existen actualmente en el mercado. En Blechexpo 2019, la feria bienal internacional dedicada a la tecnología para el tratamiento y procesado de chapa, se darán cita entre el 5 y el 8 de noviembre en Stuttgart más de 1.500 expositores y visitantes expertos para dar a conocer las novedades en productos y servicios relacionados con todos los aspectos de la transformación del metal y la chapa, tubos y perfiles.

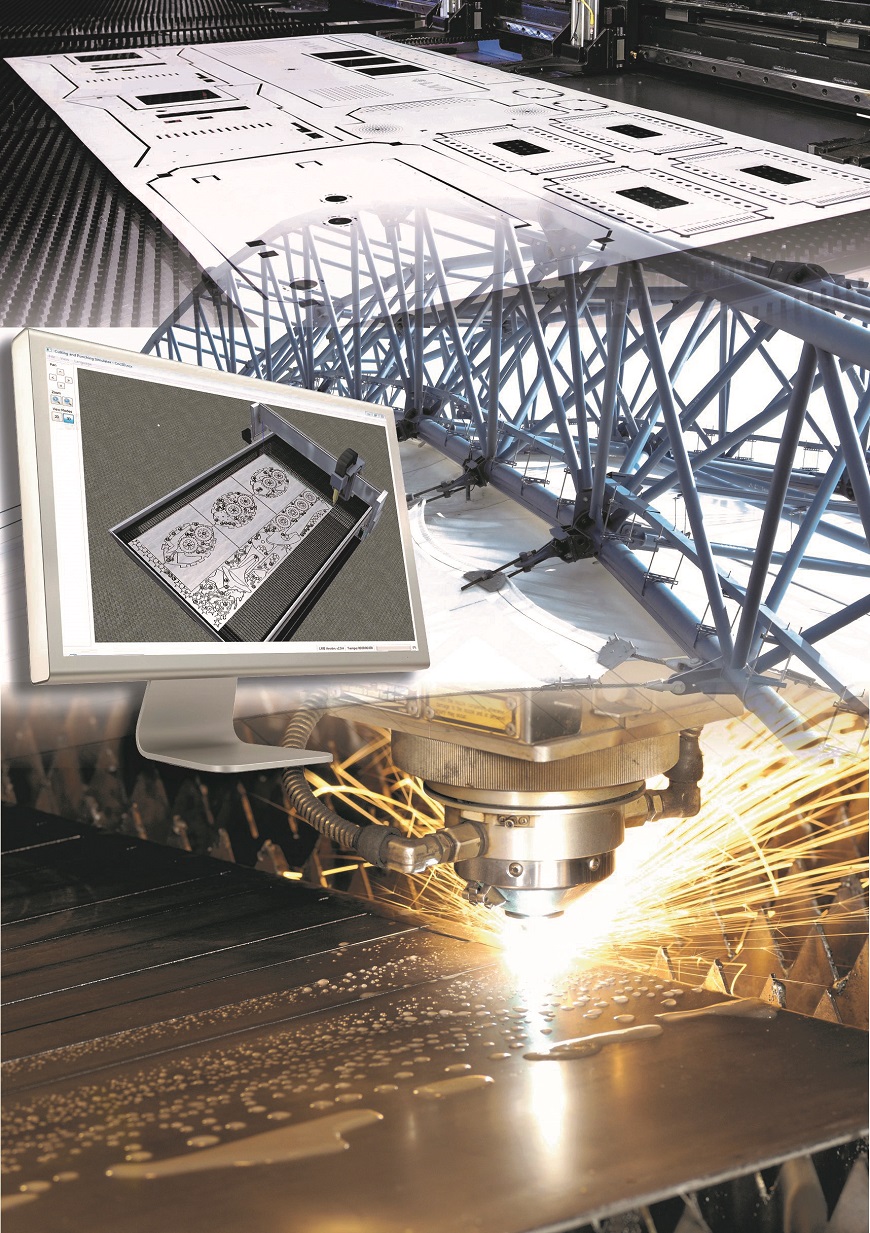

As a multinational focused on the development and sale of CAD/CAM/MES/ERP software solutions and pioneer in the digital transformation of companies in the metal sector, Lantek has confirmed its attendance at the event. There, in Pavilion 5 - Stand 5309 it willbe showcasing, among other things, its application suite on the Lantek 360 cloud platform, where the innovative online shop proposal for metal parts, Lantek MetalShop, will play a particularly important role.

“The industry in general and, specifically, that of metal, is facing a time in which the challenges posed by globalization and Industry 4.0 should be seen as a lever in order to boost the modernization of production processes and digital transformation so that we can look to a future with guarantees of being efficient and competitive businesses,” explains Joseba Montoya, sales director of Lantek Spain and Portugal. “Our company is constantly renewing itself and, at Blechexpo, we want to make sure that the new solutions developed at Lantek are within reach of the manufacturers and the attending members of the professional public. Solutions that include and combine the latest technologies (AI, cloud, IoT, machine-learning…) and trends that set the pace in advanced manufacturing to guide them in their transition towards Industry 4.0.”

The potential of the Cloud for the capacity to adapt

The obligation acquired by Lantek with the progress of the industrial sector in order to convert factories into intelligent and connected organizations ready to compete in the future have been some of the reasons that have led to the multinational developing software products that provide integral management of the manufacturers’ businesses within the industry and notably streamline any process. This results in greater competitiveness as the factories will save on time, resources, and costs as well as having more flexible structures and the capacity to quickly adapt to the market’s continuous changes.

Lantek makes all of these concepts tangible by applying the latest technologies through their software solutions. At Blechexpo, the company will make the latest developments included in their advanced manufacturing cloud platform, Lantek 360, available to the attendees, placing special emphasis on the Lantek Analytics, Control Panel, iQuoting and MetalShop solutions.

Designed to combine companies’ data as a plug and play device, Lantek Analytics minimizes the impact on the facility and never interrupts manufacturing processes. Moreover, it ensures an easy and fast learning curve so that both engineers and directors can benefit from data analytics.

“The current way of doing business is premised on adaptation to the client’s requirements, which means that you must be prepared in terms of anticipation, coordination, efficiency, and customization. Being available 24/7 is essential and this is achieved by having an online portal that allows requests to be made within the platform and offers to be processed in real time. This is what MetalShop offers,” adds Lantek’s director.

The objective of these innovations is clear: to transform the metal industry in order to take it to a new level where an automated, connected, and more intelligent production will allow the level of productivity and profitability to grow, among other things.

Blechexpo is a fair that is specifically and exclusively designed for a specialized audience. Given that it’s a technical event, it is aimed at all experts in the construction of pieces of sheet metal, groups of sheet metal and machinery, and manufacturers or experts specialized in the finishing and treatment of the sheet metal surface. The fair is not only a trading platform, but also a place for information and communication in the field of research, education and trades, where a complete overview of this sector and its supply chain is provided.

About Lantek

Lantek is a multinational which is leading the digital transformation of companies in the sheet metal and metal industry. With its patented smart manufacturing software, it enables factories to be connected, turning them into Smart Factories. It rounds off its range of services with CAD/CAM/MES/ERP solutions for companies that manufacture metal parts from sheet metal, tubes and profiles using any cutting technology (laser, plasma, oxycut, waterjet, shearing, and punching).

Founded in 1986 in the Basque Country (Spain), one of the main European hubs of machine tool development, Lantek enables the integration of sheet metal and metal processing technologies using the most advanced manufacturing management software. The company is currently the outstanding leader in its sector thanks to its capacity for innovation and commitment to internationalization. With more than 21,884 customers in over 100 countries and 20 offices in 14 countries, it has an extensive network of distributors with an international presence. In 2018, its international business contributed to 86% of its revenue.

For more information visit: www.lantek.com