Lantek, leading multinational in the development and commercialization of CAD-CAM/MES/ERP solutions and pioneer in the digital transformation of companies in the sheet metal industry, reveals the new features and improvements in the latest version of its software - Lantek Global Release 2021.

Lantek delivers multiple updates to Lantek Expert, Flex3d, MES and Integra and Analytics in its 2021 Global Release. The 2021 version is the culmination of 35 years of experience: Lantek 35th Anniversary Version.

With its Global Release 2021, Lantek continues with its commitment to offer its clients and distributors the most advanced and flexible solutions for the sheet metal market, increasing their efficiency and profitability, and helping them on the path to digital transformation.

The 2021 version is the culmination of 35 years of experience: Lantek 35th Anniversary Version. "35 years in software is a long time; many years learning from customers’ processes, from their specific cases, from their workflows and from different machines and technologies. The 2021 version is the materialization of 35 years of experience, and we are proud to release it.", says Carlos García, CTO of Lantek.

Lantek Expert

New features in the import of CAD models into Lantek Expert allow Drag and Drop and the detection of duplicate parts, making the import of part data much simpler and quicker. The software is capable of importing 3D models as assemblies and sets of parts from virtually every CAD system in the market. Now, with the Assembly to Nesting importer, it can unfold all the sheet metal parts in the model, taking account of the bending tool to be used, to arrive at an accurate 2D shape ready for nesting and cutting. Furthermore, new capabilities for managing Draft Parts make it possible to flag up parts which need further design approval before manufacture. Additionally, Lantek’s new Clean Cut technology can be applied to those contours where no lead-ins or micro-joints should be placed, avoiding potential imperfections in the final cut.

A new Expand Nest option makes it easy for the programmer to make use of unused space on the sheet by uniformly increasing the space between parts. The advantages are increased rigidity of the remaining skeleton after cutting; improved evacuation of parts during cutting and reduced chance of collisions; a reduction in heat affected zones, and a balanced weight for the skeleton when crane removal is necessary.

The new Spiral Cutting function for hole cutting destroys the material within the hole so that it falls into the machine bed. This prevents potential collisions and avoids the need for manual removal of the scrap material. It also gives a smoother and faster cut with no sharp corners and involves fewer cut start cycles.

Other improvements aimed at manufacturability include - better lead in/out positions, automatic remnant dimensioning, new micro-joint treatments, skeleton destruction options, import window customisation and improvements in cost calculations – 25 in all.

Lantek Flex3D

The tube machining market is growing strongly as is the number of new machines, devices and technologies designed to cut tubular parts. Lantek’s Global Release 2021 reflects these demands from the industry.

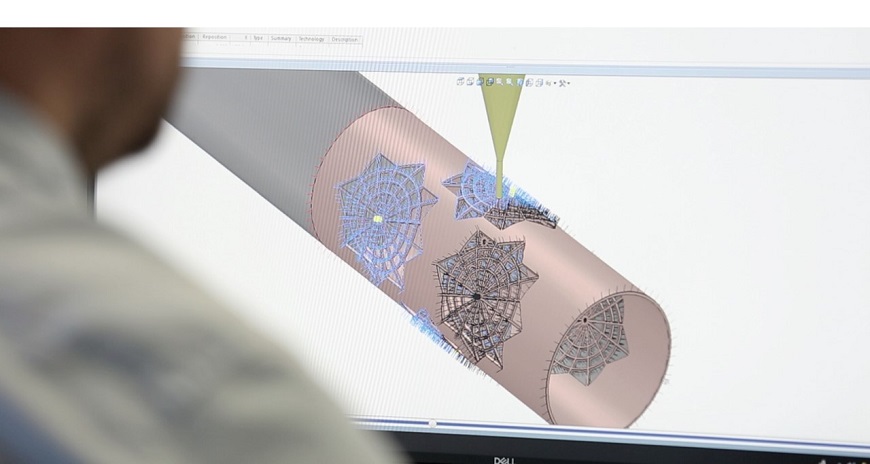

The new Toolpath Smart Designer introduces the ability to handle the importation and machining of any shape of profile, even irregular ones, making it ready for cutting any complex tube format. This capability can also be used also for the existing regular profiles, giving more flexibility to the user for efficient part cutting.

Lantek’s Steelwork parts design module has been completely redesigned to create a common and seamless user interface experience for all the machine technologies, along with a new 64-bit architecture, which has resulted in a reduction in programming time of around 15%.

Additionally, the automatic nesting engine has been improved, boosting material savings up to 5% and time savings of 28%, along with other manual capabilities for precise adjustments, different options for remnants evacuation, splitting of parts to reduce remnants generation and beam loading angle selection.

Other improvementshave been included to meet the market demands of new machining strategies and devices. These include the fast-cutting strategy for holes zones using a zig-zag machining path and improved lead-ins positioning, the support of machines with double X-axis heads or three movable supports, and other general features like acceleration handling for machining time calculation and the ability to Drag and Drop files during the importation process.

Lantek MES and Lantek Integra

Managing the workshop and accurately keeping track of resource loading, orders, delivery dates, quality and stock levels while maintaining traceability and the flexibility to react to changing circumstances are just some of the capabilities of Lantek MES and Lantek Integra.

Supporting this improved flexibility is better real-time integration with the machine control with Lantek WOS Opentalk. This gives more power and reliability, automatically reporting the job actually running on the machine. Workload Monitoring improvements help in scheduling and load monitoring, enabling accurate delivery times to be predicted for quotations and sale orders while considering the current workload, estimated running times, and pre-defined buffer and lag times for each operation.

Better integration of Lantek MES and Lantek Integra with Lantek Flex3D allows more options for the import of 3D CAD data (STEP, IGES, SAT). These changes further improve the ability of the system to create quotations.

To meet current user experience standards, Lantek has made significant improvements to its look & feel. The new dark mode theme enhances the visual ergonomics, reducing eye strain and making it possible to adjust the screen to suit the current light conditions, providing comfort for the user at night or in dark environments.

Lantek Analytics

Lantek has been working on cloud-based applications for several years and sees this as the future for software. Lantek made a giant effort to develop SaaS cloud applications. Not only does it make the software accessible from any location 24/7, but it eliminates the cost of expensive hardware, is elastic in its capacity and makes updates and new software applications easy to implement, dramatically reducing the cost of ownership.

The Global Release 2021 sees the launch of the first SaaS (Software as a Service) application in Lantek Analytics. This business Intelligence application collects relevant data every day. It can be accessed on any device from any location at any time and makes it possible to see what is happening in the factory with more than 70 KPIs and 10 filters. It has never been so easy to transparently see your business data, all packed in meaningful KPIs.

As part of the development, Lantek Analytics includes 8 new additional KPIs, the dark mode, an improvement in dashboard and filter management and Self-Service features.

8 new KPIs Machine Pause Reasons, OTIF (On Time In Full Delivery), WIP (Work In Process), Lead Time, Lead Time Evolution, Transport Cost, Transport Cost Deviation, Return Orders, will all open new valuable insights into the business.

An improvement in the Dashboard Management allows users to create and duplicate dashboards and dashboards-groups, and mark dashboards as favourites. The improvement in the Filter Management allows the user to create, edit and delete filter combinations and save them with a name so they can be quickly applied later with one click.

The Self-Service feature allows easily to create new KPIs. This is done using an easy-to-follow step by step wizard, where the user Is guided in the process and can select from more than 150 predefined measures and more than 50 filters.

Following the look and feel of other Lantek products, Analytics also has a Dark-Mode skin option, which greatly reduces eye strain making colour more vibrant.

For more information on all the new features of the version, click on this link: https://lnkd.in/eYM2QT8f