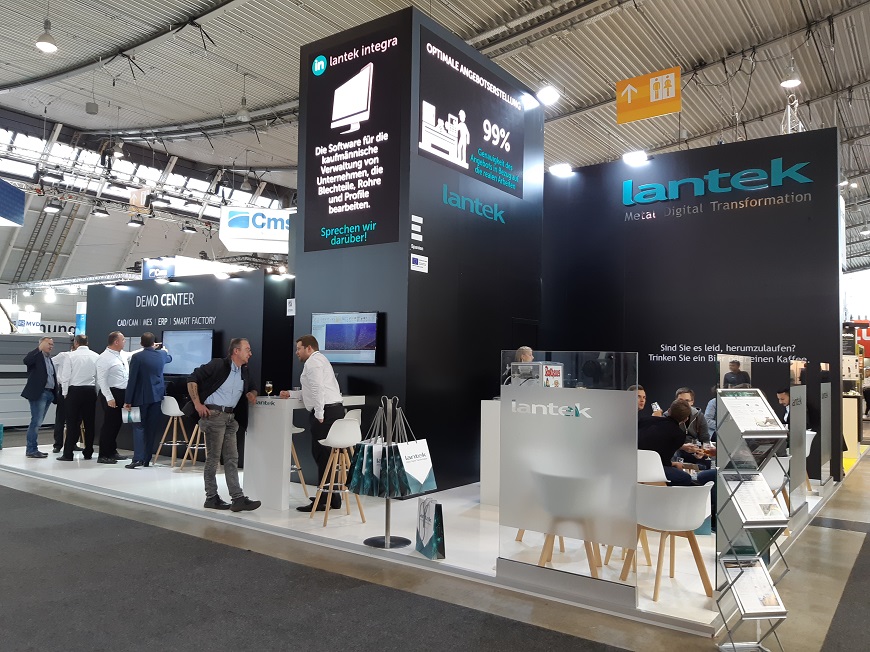

Lantek will be exhibiting at Blechexpo 2021 in Stuttgart, Hall 1, Booth 1011: From October 26 to 29, the pioneer in the digital transformation of companies in sheet metal and metalworking will present the latest features and improvements in its newest software update. Lantek Global Release 2021 highlights the power that 35 years of experience can bring to sheet metal fabrication.

With Global Release 2021, Lantek once again delivers on its promise to provide sheet metal fabricators the most advanced and flexible software solutions for greater efficiency and profitability with a pathway to digital transformation. The software update marks Lantek’s 35th anniversary and the 25th for its German subsidiary, underlining Lantek’s leadership in the development and distribution of CAD-CAM/MES/ERP solutions. "35 years is a long time in software development. Throughout the years, we have worked closely with our customers to learn from their processes, specific use cases, workflows, and about their different technologies and machines to ensure that our software meets their needs and moves them forward. We will continue to be a reliable partner to them now and in the future," says Christoph Lenhard, head of Lantek’s German office. "We are proud of Global Release 2021 and are looking forward to presenting it with all its new features at Blechexpo 2021."

Lantek Expert

New features in the import of CAD models in Lantek Expert allow drag & drop and detection of duplicate parts. This makes it easier and faster to import workpiece data – 3D models as assemblies or workpiece sets from any CAD system on the market. With the Assembly to Nesting importer, all sheet metal workpieces can now be unfolded in the model. During unfolding into a 2D geometry for cutting and bending, the intended bending tool is already taken into account. New functions for managing draft parts can be used to flag up individual workpieces that require further design verification before manufacturing. The new Clean Cut technology has been developed for contours that do not allow starting or micro-cutting on certain edges avoiding degradation of the edge finish.

The new option Expand Nest allows the programmer to use free space on the sheet by uniformly increasing the distance between workpieces. This reduces the risk of collision, makes it easier to separate and remove the workpieces from the residual grid after cutting, reduces the heat affected zone, increases the stability of the residual grid, and improves weight distribution if the residual grid has to be removed by crane.

The new Spiral Cutting function for holes destroys the residual material in holes so that it falls into the machine bed. This prevents possible collisions, yields a smoother and faster cutting process without sharp corners, and requires fewer stop-start cycles.

Other features of the 25 total enhancements for manufacturing include optimized start/cut positions, automatic remnant dimensioning, new micro-joint treatments, skeleton destruction options, import window customization, and improvements in cost calculation.

Lantek Flex3d

The market for tube machining is becoming increasingly important and the variety of machines, equipment, and technologies for cutting tube workpieces is constantly growing. With the new Toolpath Smart Designer in Lantek Flex3d, profiles of any shape can be imported and edited, including irregular contours, making it possible to cut a wide variety of complex pipe formats. This feature gives the user more flexibility for efficient workpiece cutting and can even be applied to existing normal profiles.

The design module for profile parts has also been completely redesigned and now offers uniform and seamless interfaces to all machine technologies. The basis is a new 64-bit architecture, which reduces process time by around 15 percent.

The optimized automatic nesting makes further material savings of up to 5 percent and time savings of up to 28 percent. In addition, it allows parts to be moved manually, offers various options for disposing of remnants, splitting of workpieces to reduce the amount of scrap, or selecting the loading angle of the profiles during clamping.

Other enhancements include a quick-cut mode for holes using zig-zag movements, improved start positioning, support for machines with two X-axes or three moving supports, and accelerated calculation of machining time and drag-and-drop for importing files.

Lantek MES and Lantek Integra

Lantek WOS Opentalk optimizes real-time integration with the machine control. This program provides greater performance and reliability by reporting the work order currently being processed by the machine.

Improvements in resource utilization visibility help with planning and monitoring. This enables delivery dates to be accurately predicted for estimates and customer orders – taking into account current workload, expected uptime, and predefined buffer times and delays. Better integration of Lantek MES and Lantek Integra with Lantek Flex3d provides more options for importing 3D CAD data (STEP, IGES, SAT). This additionally increases the system’s ability to create quotations.

To meet current standards in user experience, Lantek has significantly changed the look and feel of the interface. For example, the new dark mode enhances the visual experience by reducing eye strain and increasing comfort for working at night or in dark environments by adjusting the screen to current lighting conditions.

Lantek Analytics

Lantek sees cloud-based applications as the future of software. Accordingly, the IT expert invested heavily in the development SaaS cloud applications (SaaS = Software as a Service). This not only makes software available from any location 24/7. It also eliminates the cost of expensive hardware and offers great flexibility in terms of computing power, updates and integration of new software tools. SaaS applications drastically reduce acquisition and operating costs.

Global Release 2021 saw the launch of Lantek Analytics, the first SaaS application. Accessible at any time from any device and any location, this business intelligence tool gives users the ability to see what is currently happening in the factory with more than 70 metrics and 10 filters. It has never been so easy to transparently see business data in the form of significant metrics.

Lantek Analytics 2021 offers a dark mode, dashboard and filter management enhancements, a self-service feature, and eight new additional KPIs that provide valuable business insights: reasons for machine downtime, OTIF (on-time-in-full – complete and on-time delivery), WIP (work-in-process inventory), lead time, lead time evolution, transportation cost, transportation cost variance and returns.

Lantek iQuoting and MetalShop

Lantek iQuoting and MetalShop are also cloud-based applications that make it easy to create quotes quickly and automatically – from anywhere, using any internet-enabled device.

Lantek MetalShop was developed for customers who use Lantek iQuoting and want to offer their customers 24/7 accessibility with online quoting and ordering. E-commerce based on the MetalShop tool also offers contract manufacturers in particular, the possibility of relieving their sales department from the need to process simple standard products, while at the same time attracting new customers and markets that prefer online platforms for their business.

See for yourself at Blechexpo from October 26-29 at Messe Stuttgart, Hall 1, Booth 1011, how Lantek’s software solutions increase the efficiency and profitability of sheet metal manufacturers and supports them on their digital transformation journey.

Über Lantek:

Lantek ist ein multinationales Unternehmen, das in der digitalen Transformation von Unternehmen der Blech- und Metallindustrie führend ist. Mit seiner patentierten intelligenten Fertigungssoftware ermöglicht es die Vernetzung von Produktionsstätten und macht sie zu Smart Factorys. Das Dienstleistungsangebot wird abgerundet durch CAD/CAM/MES/ERP-Softwarelösungen für Hersteller von Blechteilen, Rohren und Profilen mit unterschiedlichen Schneid-(Laser, Plasma, Autogen, Wasserstrahl, Scheren) und Stanzverfahren.

Gegründet 1986 im Baskenland (Spanien), einem der wichtigsten europäischen Zentren für die Entwicklung von Werkzeugmaschinen, ermöglicht das Unternehmen die Integration von Blech- und Metallbearbeitungstechnologien mit modernster Software für das Produktionsmanagement. Lantek ist aktuell Marktführer in der Branche, dank seiner Innovationskompetenz und konsequenten Internationalisierungsstrategie. Mit mehr als 27.000 Kunden in über 100 Ländern und 20 eigenen Büros in 14 Ländern verfügt die Firma über ein umfangreiches Netz an Distributoren mit weltweiter Präsenz. Im Jahr 2020 erwirtschafteten die internationalen Aktivitäten 88 Prozent des Umsatzes.