Author: Luis Galo, Data Scientist at Lantek

One consequence of the implementation of Machine Learning (ML) is the introduction of methodologies to improve the quality of the life cycle of an artificial intelligence product, among them, DevOps which aims to orchestrate work between teams, such as development, operations and now data science using software that integrates people, processes and technology to offer higher quality products in less time, minimizing errors throughout their whole life cycle.

The emergence of artificial intelligence models takes this one step further, making it necessary to add a layer so that learned knowledge models and their automation can be managed. The result is MLOPS (Machine learning + DEVOPS).

MLOps is the key to successful, scaled machine learning projects. What is MLOps? It’s the collaboration between data science and IT teams designed to accelerate the whole life cycle of developing models, implementation and monitoring in a way that enables companies to fully embrace AI and realize the potential of AI for their business.

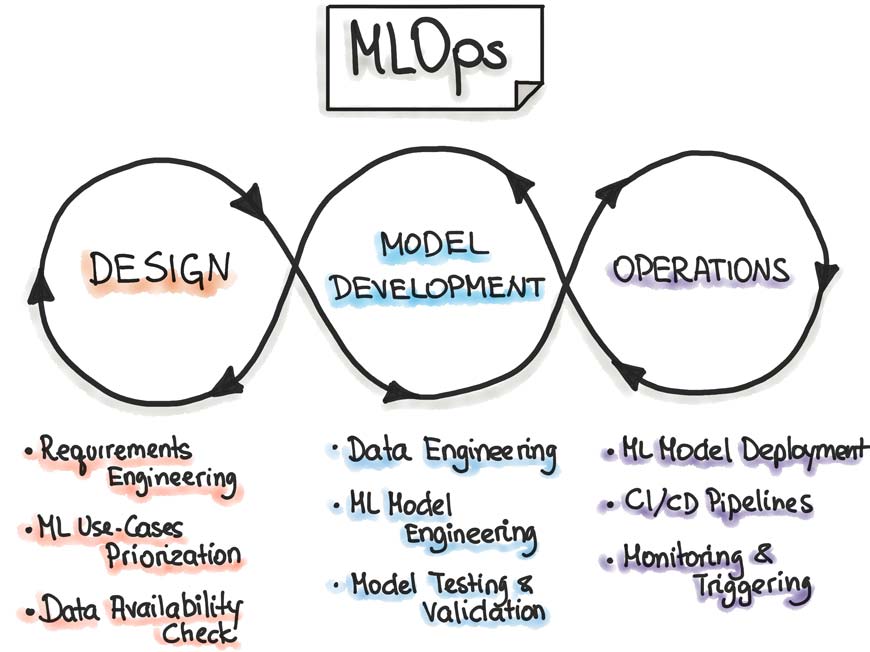

MLOps works in three phases:

Software design: depending on the user’s requirements, a machine learning solution is designed to meet their needs, be it manufacturing more quickly, reducing costs by reducing scrap generation, improving productivity or making order predictions. This phase is where the extracted data is collected and analyzed to offer ad hoc solutions.

Experimentation and development: in this phase the machine learning model is applied to production to test it and polish the defined algorithm in order to offer a machine learning model that is consistent in quality.

Operations: The model developed using DevOps practices, such as testing, version control, monitoring, etc. is implemented.

The challenge is to launch these models into production in a way that’s easy to use, automating the processes as much as possible in order to limit the intervention of engineers in deployments, while maintaining the quality of software and models.

To this end, the models are packaged, uploaded to the cloud and stored securely. Each time that the parameters are modified, another version of the model is automatically created, which is then once again subjected to a quality control process. Once deployed in the Cloud, the user can use this new model adjusted to the new reality of their factory.

While the people working on the different processes carry out their daily tasks, the system learns to add improvements and make processes more efficient. Because if they are not fed information, if they are not aided in that learning process, they become obsolete. Imagine, for example, that a new type of material is developed. If it’s not explained to the machine, it won’t understand it and will mark it as an error.

Use of MLOps in the metal and sheet metal industry

At Lantek, we use MLOPS to ensure the quality and control of the models deployed in the cloud with criteria of equity and security, among others. Through our Lantek 360 platform, our CAD/CAM and MES software programs are able to connect to each of the machines and collect their data in order to digitize them, while also digitizing the manufacturing process of the part itself.

Now, thanks to Machine Learning, we are able to model and make rapid future predictions of each route involved in the manufacturing process. From the moment the order is placed, a quote is prepared, passed to purchases and, later, sent to design and production. That is, we have a comprehensive overview of the whole process.

Subsequently, with Artificial Intelligence (AI) tools and MLOps, we can not only reflect the time the machine has been running, the energy it has consumed or the number of parts produced, but also quantify how much scrap has been produced or how many operators have been involved in production and ensure the quality of the models over time.

In terms of quoting, as we know, in the metal and sheet metal industry, drawing up quotes is a complex task which involves many variables and several departments and takes a lot of time. With AI, quotes are created and multiplied more quickly and, with MLOPS, we make sure that they continue to work over time.

The idea of these MLOPs projects is that, behind the people, there is intelligent software to offer advice on configuration. Then, the operator can decide whether to apply the proposal or not, but, of course, this decision can be made much faster and easier than at present. In this case, the amount of knowledge generated (models) is so vast and variable over time that it would be impossible to manage AI models without applying MLOPS methodologies and maintain their quality throughout the product lifecycle. Ultimately, the end goal is to optimize the plant’s production processes as much as possible so that manufacturing is as cheap as possible (AI), to make optimization durable over time (MLOPS) in a simple way. Optimization that is especially aimed at small and medium-sized companies so that they can be as competitive as large ones, without the need for experts in software architecture or data science, who already use MLOps systems to be more profitable and efficient in the deployment of their AI models.

In the world that we’re living in, we all have to get on board with Industry 4.0 and our task as a driving force is to democratize the use of artificial intelligence tools for optimizing resources, making them usable and accessible to any factory.