Industry 4.0 is a collective term embracing contemporary automation, data exchange, and manufacturing technologies, directed at the value chain organization which draws together Cyber-Physical Systems (CPS), the Internet of Things (IoT) and the Internet of Services (IoS).

Industry 4.0 facilitates the vision and execution of a "Smart Factory" where cyber-physical systems monitor physical processes, create a virtual copy of the physical world, and make decentralized decisions. Over the Internet of Things, cyber-physical systems communicate and cooperate with each other and with humans in real time. Via the Internet of Services, both internal and cross-organizational services are offered and utilized by participants of the value chain.

The aim of Industry 4.0 is to improve the competitiveness of our company thanks to technology. We need to be efficient and able to make decisions in the shortest time possible. Every second of a machine not in use is money wasted. With that said, nor should we be using all available machine capacity if we aren´t sure that it is profitable. In the end, all actions must be measured so we understand the effect they will have on our Income Statement.

So how do we move towards Industry 4.0? The answer is simple: Digitalizing the factory. To do so we need to explicitly define the manufacturing processes, to choose our key operational indicators and to define how we are going to achieve them. We then have to house these processes and indicators within a management system that allows us to view their status and to take operational decisions and steps to improve.

Once we have specified the processes we must then incorporate intelligence to digitalize them and see continuous improvement. We have to support them with a production management system that is well established in a single software application or through an integration of several pieces of software that cooperate with each other. We will figure out at what stage of the process we need to get information and of what type. Knowing what information will allow us to make the right decisions.

We will then design the tools to get the right information, at the right time, and to make the right decision.

Once digitalized, we will be able to collect relevant information, achieve real-time data capture, and measure what is actually going on in our plant. We can extract behavior patterns and efficiency analyses for our factory.

From thereon, knowing what our key business factors are, we will be able to assess how they are being affected by processes and results collected during the analysis. With these analyses, based on real data taken directly from the operation, we can flesh out improvements in different areas.

All this brings a number of truly significant benefits: manual actions are simplified, the margin for error is reduced, and automating the running of processes and decision making becomes more intuitive. Once we have managed to get an advanced control of the plant, we will be able to simulate what might happen if we make changes. We will make decisions taking into account the possible effect that manufacturing models, generated from the current factory set-up, predict for us.

Lantek today is one of the drivers of Industry 4.0. Lantek interprets Industry 4.0 and applies it to companies that produce sheet metal parts, metal tubes and profiles, developing multiple functionality, that is today in place in customers all over the world. For example:

These are just some of the possible functionalities within a broad range that we can achieve thanks to the technologies already available, with no need to wait for what the future may hold.

To keep improving, the first step is to know our business and for that we need to digitalize it. Lantek Factory is the way forward for implementing these principles and ensuring that the competitiveness of our production plant makes us the preferred choice for our customers.

About Lantek

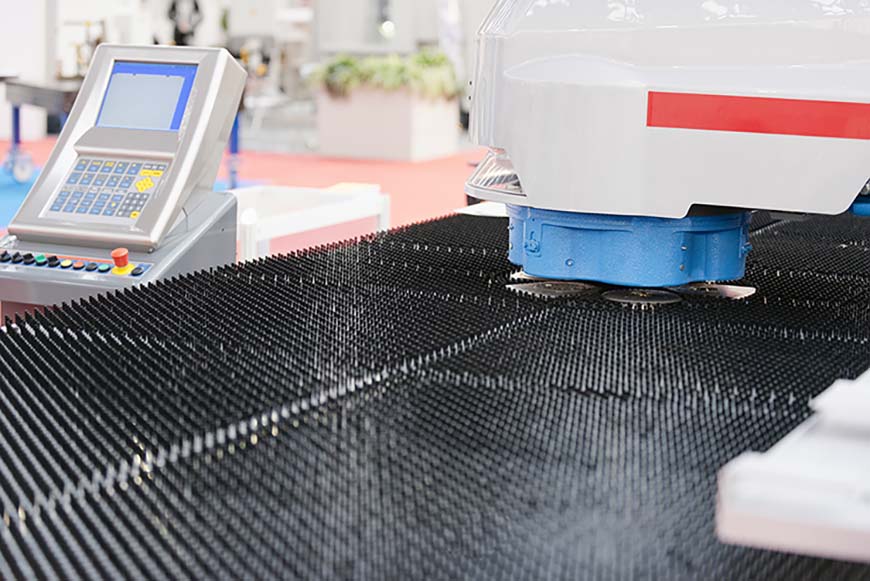

Lantek provides software solutions CAD/CAM/MES/ERP for companies fabricating sheet metal, tubes, and beams with any cutting(laser, plasma, oxy-cut, water jet, shear) and punching technology. Lantek integrates the most advanced nesting software in the industry with the highest standards in manufacturing management solutions.

Its capacity for innovation and its firm commitment to internationalization and emerging markets have led Lantek, founded in 1986 in the Basque Country and with central offices in Vitoria-Gasteiz (Alava), to devise a global-local strategy, which has meant it has become a global reference within the industry with its CAD/CAM/MES/ERP solutions. Today, the company has over 17,000 customers in over 100 countries and its own offices in 15 countries, in addition to an extensive network of distributors that are present throughout the world. In 2015 its international operations provided 88% of its turnover.

For more information, visit: www.lantek.com or request more details at: marketing@lanteksms.com