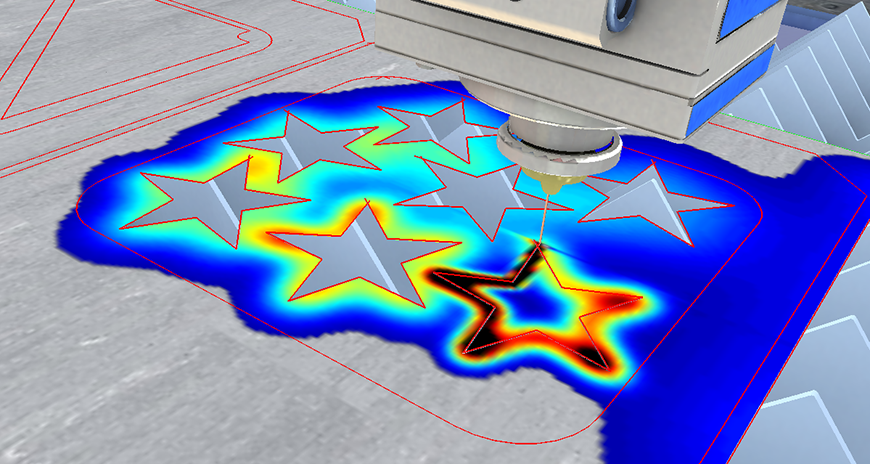

As part of its continuous improvement R&D&I strategy, the multinational Lantek, pioneer in the digital transformation of the sheet metal and fabrication sector, in collaboration with Vicomtech, the Visual Interaction and Communications Technologies Center Foundation, has launched BeroSim. The aim of the project has been to develop a 3D simulation software system that allows the user to calculate graphically and interactively how heat sources affect sheet metal during the laser or plasma cutting process.

With this initiative, both organizations have taken a step further in their aim of offering the industry innovative solutions and services that respond to its needs and that provide real added value, allowing companies to adapt to a changing and increasingly competitive global environment, driven forward by industry 4.0 and advanced manufacturing.

The simulation of the impact of heat on the sheet metal cutting processes enables the selection of the best sheet metal strategy and cutting order, substantially improving performance since it possible to anticipate and detect possible unforeseen anomalies during the layout phase. By simulating the process using BeroSim the effects of cutting do not need to be tested on the actual machine. This results in savings in machine time, materials and energy, while at the same time lessening the risk of possible breakdowns or workplace accidents.

Now, with BeroSim, the user will be able to see, through a simulation, how heat propagates and is distributed in the sheet metal as it is cut and how this affects the material. Plasma and laser technologies locally increase the overall temperature of the sheet metal which modifies the properties of the material and can alter its characteristics (thickness, etc.).

With BeroSim, engineers can use the simulation to define the sheet metal cutting strategy and the cutting and machining order, preventing possible material deformation during cutting to obtain optimum quality products.

Likewise, the user can correct the cutting path and trajectory of the machine to maintain the quality of the sheet metal products.

"Digital transformation has become highly important in the industrial sector, which needs advanced technological solutions that provide added value, something that is only possible with research and innovation," explains Dr. Iñigo Barandiaran, Head of Vicomtech’s Department of Industry and Advanced Manufacturing. "The industrial sector must continue to be an economic engine and guarantor of stable employment, and this will be achieved with the help of technology."

"With BeroSim, we contribute to this process of change and to the modernization of the sheet metal machining, simulation and verification sector, providing a set of functionalities and innovative capabilities that provide greater efficiency to production processes. This enables the optimization of material, human and economic resources,” says Susana García, head of CAD/CAM systems development at Lantek. "This collaboration with Vicomtech helps us to promote the implementation of productive models and methodologies that will allow the users of our solutions to achieve greater competitiveness and efficiency."

The BeroSim project reinforces the position of Lantek as one of the leaders in innovation worldwide in a very competitive and mature market, providing its Lantek Expert product with powerful differentiating features. At the same time, it supports the role of Vicomtech as a promoter and driver of applied research and a facilitator for the development of new product prototypes.

Moreover, the technological cooperation between Lantek and Vicomtech consolidates the relationship between both companies and complements their efforts in terms of innovation for the industrial sector.

The BeroSim project represents a scientific breakthrough regarding the state of the art in sheet metal technology and has been recognized by the prestigious Journal of Manufacturing Science and Engineering. The journal published an article about the research carried out by Lantek and Vicomtech concerning interactive 3D simulation and the influence of heat during the sheet metal cutting processes. "Understanding how heat sources affect sheet metal cutting processes is essential in the design of efficient simulation tools. The success of BeroSim is a consequence of the fluid relationship between Lantek and Vicomtech,” says Dr. Aitor Moreno, Vicomtech researcher and expert in industrial process simulation techniques.

About Lantek

Lantek is a multinational company which is leading the digital transformation of companies in the industrial sector of sheet metal and metal. It offers its own software solutions in business manufacturing intelligence which enable connecting the factories thereby converting them into smart factories. It rounds off its range with the development of CAD/CAM/MES/ERP solutions for companies that manufacture metal parts from sheet, tubes and profiles with any cutting technology (laser, plasma, oxycut, waterjet, shearing and punching).

Founded in 1986 in the Basque Country (Spain), one of the main European hubs of machine tool development, Lantek enables the integration of sheet metal and metal processing technologies using the most demanding advanced manufacturing management software. The company is currently the outstanding leader in its sector thanks to its capacity for innovation and commitment to internationalization. With more than 19,000 clients in over 100 countries and its own offices in 15 countries, it has an extensive network of distributors with a worldwide presence. In 2016, its international business contributed to 85% of its revenue.

For more information visit: www.lantek.com or ask for more details at: marketing@lanteksms.com

About Vicomtech

Vicomtech is an applied research center, founded in 2001 and located in the Gipuzkoa Science and Technology Park, which develops applied research projects in the fields of Advanced Interaction, Computer Graphics, Computer Vision, Data Analytics and Language Technologies

All of its activities are regulated by the R&D&I management system, activities such as the continuous improvement of results and its measurement, the optimization of technological innovation processes, as well as the transfer and generation of knowledge, thus ensuring that it always uses high quality methodologies. Vicomtech has both the ISO 9001:2015 and UNE 166002:2014 certificates that place it at the forefront of research quality and demonstrate its commitment to the quality of its processes.