LaserMaster has been using Lantek Expert CAD/CAM software for six years and has just upgraded to the latest version and added the Lantek Integra ERP system.

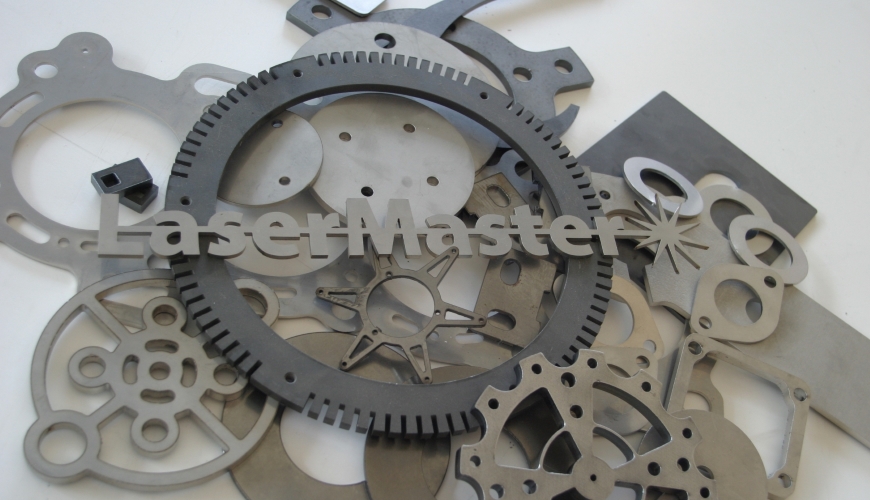

LaserMaster has been using Lantek Expert CAD/CAM software for six years and has just upgraded to the latest version and added the Lantek Integra ERP system. Formed 11 years ago, LaserMaster initially manufactured its own range of carpet cleaning machines, but now the bulk of its business is subcontract sheet metal and fabricated products for a wide variety of industries including aerospace, motor sport and automation. Previously it used CAD/CAM software from another leading supplier, but poor levels of support led it to replace the system with Lantek Expert in 2007.

Early in 2013 the company invested in a new Bystronic BySprint 4kw fibre optic laser with ByTrans automated sheet load/unload and, at the same time, upgraded its Lantek Expert software and installed Lantek Integra ERP, replacing its existing Bystronic 3015 3.5kw laser. Tim Hicks, CADCAM Engineer at LaserMaster says, “We upgraded the software to complement the more efficient cutting we can get from the new Bystronic, which has been a £0.5m investment for us. We have had experience with all the other leading CADCAM systems, and they have not been able to touch Lantek for performance and nesting efficiency.”

To fill the available capacity that the new machine has created, LaserMaster needs to produce around 50 quotes every day. Tim Hicks says, “It is vital for us to get the quotes done very quickly. All the parts we produce are different with the occasional repeat order. Lantek Integra communicates with Lantek Expert to calculate material usage and cutting times. It also includes information about material costs to give us accurate selling prices. In addition, the system monitors the success rates for our quotations so we can see how we are performing against our sales targets.”

With Lantek Manager, the company can keep track of the status of each job and its location in the workshop ready for secondary operations such as bending or painting. The solution is also able to generate sales orders, invoices and delivery notes, all related to the original quotation. Tim Hicks adds, “We can log into the system to check that no parts are missed and that all the operations have been completed.”

The new machine runs 4-5 hours most nights with the automatic sheet loader. Machine utilisation during the day is around 70%. Parts are tagged into the sheet for efficient handling and the Lantek Expert automated nesting is used without any manual intervention 99.9% of the time to dynamically nest the mix of parts on order. Tim Hicks says, “The new Bystronic and Lantek software combination is 50% more efficient than our previous setup and we have the potential to produce four times more work than before. We are working towards making this a reality. Already we are seeing more quotations turn into orders. Lantek Expert, Lantek Manager and Lantek Integra are an essential part of this success. We looked at other software, but it was too slow and laborious. In our opinion, Lantek has, by far, the best solution for sheet metal applications.”

About Lantek

Lantek is a leading global multinational in the development and commercialisation of software solutions for the sheet metal and structural steel industry. Its capacity for innovation and its firm commitment to internationalisation and the development of emerging markets has led Lantek, founded in 1986 in the Basque Country and with head offices in Vitoria (Alava), to become a global reference in the industry with its CAD/CAM/MES/ERP solutions. Today, the company has over 13,000 clients in more than 100 countries, offices in 14 countries, and a wide network of distributors providing worldwide coverage. In 2012 its international operations provided 85% of its turnover.

For more information visit our website: www.lantek.com or request more details at: marketing@lanteksms.com