The new layout and Halls for MACH 2018 and the growing confidence within the British manufacturing industry made the show one of the most successful for Lantek’s sheet metal CADCAM software, digital transformation solutions and Lantek Synergy concept.

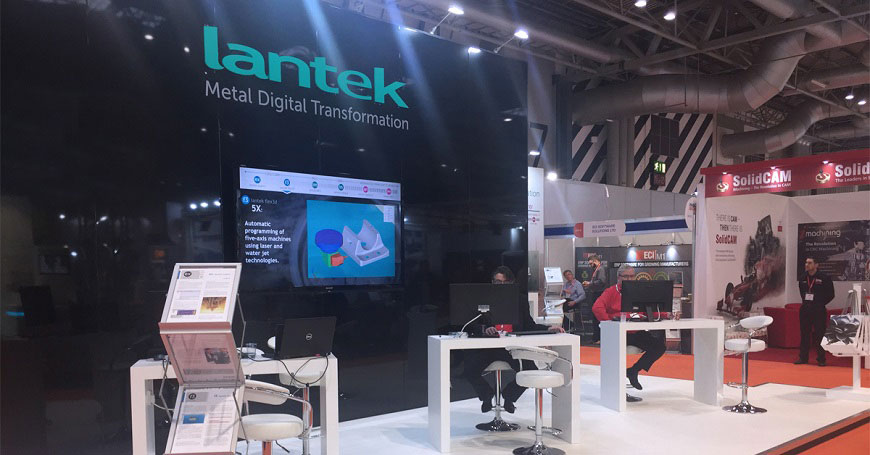

Lantek’s large, eye catching stand attracted a continuous stream of visitors. Rob Powell, Commercial Director for Lantek says, “We are confident that MACH 2018 will yield some very positive results for us. The quality and number of the enquiries we took on the stand showed that manufacturers could see and understand the benefits in investing in our market leading Lantek Expert CADCAM software. Additionally, many more companies were preparing to start on the path of digital transformation. We helped them to recognise how it was relevant to the future prosperity of their businesses and that having the ability to build on their existing business processes, in partnership with Lantek, made it affordable and easier to implement.”

For companies in the sheet metal and fabrication industries Lantek demonstrated how manufacturers could get the best performance from their cutting machines with its Lantek Expert software, leaving them able to choose their preferred machine manufacturer and mix of processes including punching, laser, waterjet, plasma and flame cutting, programming them all from one system while optimising machine performance and material utilisation.

Digital transformation and Industry 4.0 were the main topics at MACH 2018. Lantek has developed its software so that companies in the sheet metal industry can start on the road to digitalization with minimum effort. It is clear that this transformation is the next revolution in manufacturing, enabling companies to simplify and automate the majority of their business processes and customer relationships and, with the information gathered, make intelligent decisions for production processes, investment and increased customer satisfaction. The Lantek Synergy concept goes further, linking customers and suppliers to the business, building a mutually supportive network, which will make it easier to do business and, which will encourage customer loyalty and hence higher levels of repeat and new business.

Lantek’s policy of collaborating with machine manufacturers and suppliers is also paying dividends. By working with leading companies in the industry, Lantek is helping them to meet their aspirations in the implementation of Industry 4.0 for their customers, linking the machine into the overall business system, maximising OEE, reducing costs and increasing profitability. At MACH 2018 these relationships drove even more traffic to the Lantek stand.

Rob Powell concludes, “MACH is the most important show for us in the UK. It is a major showcase for advanced technology and it has certainly helped us to demonstrate our leadership in the sheet metal and fabrication market and to explain the advantages of digital transformation to customers and prospects alike. It is clear that our Synergy concept designed for the sheet metal and fabrication industry is unique and that early adopters will reap the most benefits. We will definitely be back for MACH 2020.”

About Lantek

Lantek provides software solutions CAD/CAM/MES/ERP for companies fabricating sheet metal, tubes, and beams with any cutting (laser, plasma, oxy-cut, water jet, shear) and punching technology. Lantek integrates the most advanced nesting software in the industry with the highest standards in manufacturing management solutions.

Its capacity for innovation and its firm commitment to internationalization and emerging markets have led Lantek, founded in 1986 in the Basque Country and with central offices in Vitoria-Gasteiz (Alava), to devise a global-local strategy, which has meant it has become a global reference within the industry with its CAD/CAM/MES/ERP solutions. Today, the company has over 20,000 customers in over 100 countries and its own offices in 14 countries, in addition to an extensive network of distributors that are present throughout the world. In 2017 its international operations provided 86% of its turnover.

For more information, visit: www.lantek.com or request more details at: marketing@lanteksms.com