Lantek has enhanced its Lantek Flex3d software for the design, folding/unfolding, and 3D cutting of tubes, profiles, and sheet metal parts as part of the latest 2011 version of its software.

The new features incorporated into Lantek Flex3d represent a major advance for the sheet metal industry, providing it with a more flexible solution with comprehensive functionality, capable of being tailored to meet the needs of individual users. Lantek Flex3d has the power to manage large-scale projects and incorporates the most advanced 3D design technologies in its architecture. Lantek has also significantly improved the software’s CAD data exchange capabilities, with speed improvements of 300%.

Lantek Flex3d V2011, like all the previous versions, is fully integrated with all of the company’s other applications, greatly simplifying and easing the management and coordination of manufacturing processes. These new developments introduced by Lantek are an effective response to the demands of companies within the industry enabling them to increase their productivity and keep one step ahead in the market.

Modular solution

Lantek Flex3d comprises eight specific modules, enabling the user to: perform folding and unfolding tasks, work with tubes or profiles, carry out integrated design and manufacture withSolidWorks®, Autodesk Inventor®, Solid Edge®, CATIA®, Creo Elements/Pro® and Siemens NX®, automate the programming of laser and waterjet 5-axis sheet metal cutting machines, and design and cut standard profiles using the Lantek Flex3d Steelwork module.

In the 2011 version of Lantek’s software, all the modules incorporate new intuitive functionality which makes 3D design and manufacture faster and easier for the user. Within the Lantek Flex3d product family the company has focused on three modules in particular.

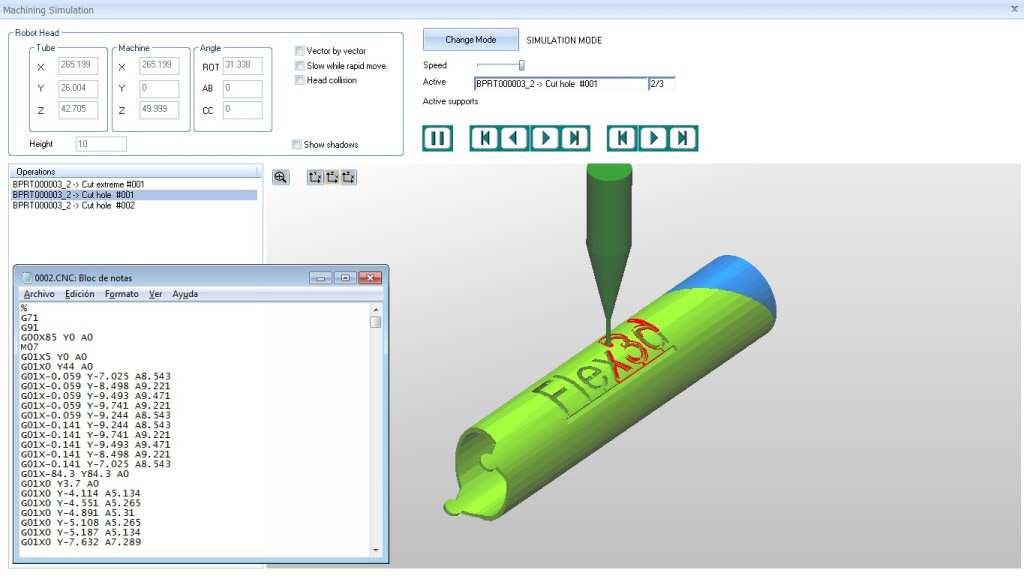

Lantek Flex3d Tubes, developed for the design and cutting of tubular components includes: new geometry macros, the ability to automatically assign specific cutting technology to each machining parameter, improved simulation of 5-axis cutting, and more automated nesting capability. These new features make it much easier for users to visualize the real results of their tube cutting operations.

Lantek Flex3d Steelwork, intended for the design and cutting of steelwork profiles, is easier to use. Customization enables engineers to tailor the system to their requirements and now includes automatic screw and countersink management to ISO standards, as well as to the special requirements of each company. Furthermore, machining operations can be visualized and checked faster and more efficiently in the new version.

Lantek Flex3d 5x, aimed at programming 3D sheet metal cutting machines with 5-axis heads, benefits from some important improvements. Totally compatible with the main 3D design systems used in the sheet metal industry, the software enables users to import parts in virtually any format ready for 5-axis cutting. Intuitive commands lead the user through the programming phase greatly simplifying the process. Other innovations include new workbench positioning methodology, automatic machining algorithms, and fast and flexible verification and simulation, all designed to improve productivity and reliability.

Mario Rodríguez, Product Manager Flex3d says, “The developments in the latest versions of our software have produced a powerful, flexible, agile and enormously intuitive solution that makes 3D part design and manufacture easier, in a process that can be tailored to the needs of individual companies. The new version is a major step forward for the industry and is evidence of Lantek’s commitment to producing innovating systems which include the latest technology, to help in the simplification of design and manufacture, and to improve competitiveness within the metal processing sector.”

About Lantek

Lantek is a world multi-national leader in the development and marketing of CAD/CAM and ERP integral solutions for the machine tool section. The capacity for innovation and its determined quest for internationalization have led to Lantek, established in the Basque Country in 1986, becoming a worldwide reference with its Lantek Expert solutions for cutting and punching sheet metal. Today, the company has over 11,000 clients in more than 100 countries, including its own offices in Spain (Vitoria-Gasteiz), the United States, Germany, Argentina, Brazil, Italy, the United Kingdom, China, South Korea, France, Japan, India, Poland, Mexico, Turkey and the Czech Republic, together with a network of distributors spreading its presence throughout the world. Its international business in 2010 contributed to 84% of its volume.

For further information, please visit: www.lantek.com marketing@lantek.es